Wool is synonymous with luxury, warmth, and quality. However, it has one infamous drawback: the dreaded "Hand Wash Only" label. This inconvenience is a major barrier for modern consumers. The good news? Technology has solved this problem. The key to unlocking the full potential of your wool products is creating machine-washable wool. This guide will explain the science behind wool felting and how a professional wool treatment with an anti-felting agent can transform your garments into easy-care, high-value items. For producers of premium woolens, this is a game-changing upgrade. Discover our advanced solutions for wool processing.

Why does wool shrink and mat in the wash? To understand the solution, we must first look at the unique, microscopic structure of the wool fiber itself.

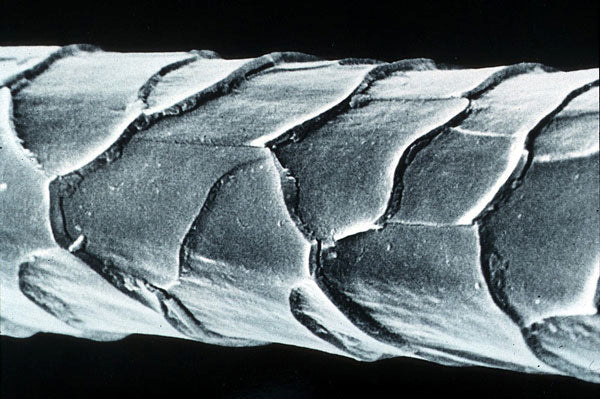

If you look at a wool fiber under a microscope, you'll see it's not smooth. The surface is covered in tiny, overlapping fiber scales, much like the tiles on a roof. These scales all point in one direction, from the root to the tip of the fiber.

When wool gets wet and is agitated (like in a washing machine), these scales open up. Due to their directional nature, the fibers can move easily in one direction but resist moving back. This creates a "directional frictional effect." It's like a one-way street; the fibers move towards their root, lock into each other, and cannot untangle. The result is felting: the irreversible shrinking and matting of the fabric.

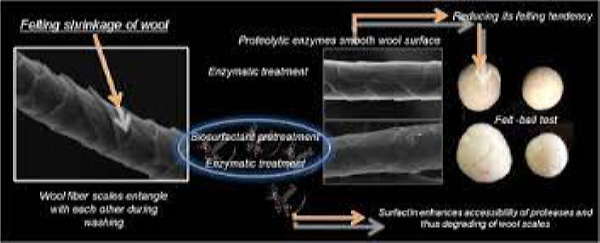

To create machine-washable wool, we must neutralize this directional frictional effect. This is achieved by modifying the surface of the fiber scales with a specialized anti-felting agent.

The most common and effective method is a controlled chemical treatment. This process, often a mild chlorination or oxidation, targets the sharp edges of the scales. It can either completely remove the scales or smooth their edges down, effectively blunting the "barbs" that cause felting.

With the scale edges smoothed or removed, the wool fibers lose their ability to lock together. They can now glide past one another in the wash without tangling. This modification is the secret behind durable, reliable, machine-washable wool.

At Taiyang Chemical, we provide a professional and reliable solution for this process: TY1-35 Scaling Tablets. This product is a specialized anti-felting agent designed for uniform and controlled wool mercerizing.

The key to a successful treatment is uniformity. TY1-35 ensures a consistent and even oxidation effect across the entire batch, providing an excellent and reliable anti-felting finish.

A high-quality wool treatment should enhance, not detract from, the fiber's natural beauty. TY1-35 is formulated to cause minimal fiber damage, preserving the wool's strength. Furthermore, the process imparts a lasting soft luster, improving the final appearance of the product.

Achieving the best results requires a complete, multi-step process. Here is a typical guide using our scaling tablets:

The ultimate goal of this wool treatment is to meet the globally recognized standards for easy-care wool.

The International Wool Secretariat (the organization behind the Woolmark brand) has rigorous testing protocols for garments labeled as "machine-washable." These tests ensure the product shows minimal shrinkage or change in appearance after repeated machine washing cycles.

By following the recommended process with TY1-35 Scaling Tablets, manufacturers can confidently produce wool products that meet and even exceed these stringent international standards. This allows you to use the powerful "machine-washable" claim in your marketing. For specific guidance, you can always request a technical consultation.

The ability to label a wool garment as "machine-washable" is a powerful competitive advantage. It transforms a luxury item into a practical, everyday luxury. This wool treatment with a professional anti-felting agent like TY1-35 is a direct investment in your product's marketability and value.

Ready to elevate your wool collection to the next level? Contact us to learn more about TY1-35 Scaling Tablets and start producing premium, easy-care wool.

Does anti-felting treatment affect the feel of wool? When performed correctly with a high-quality agent like TY1-35, the treatment causes minimal fiber damage. The process is designed to preserve the wool's natural softness, warmth, and breathability. In fact, the added soft luster often improves the final hand feel.

What is dechlorination? Dechlorination is the process of neutralizing and removing any residual chlorine from the fabric after the main treatment. It is an absolutely essential step. If chlorine is left on the fiber, it can continue to degrade the wool over time, leading to strength loss and yellowing.

The process is specifically designed for modifying the scales of wool fibers. It is highly effective on 100% wool and high-percentage wool blends. For blends with a low wool content, the effect may be less pronounced.

How do I dissolve solid granules for use? As noted in our product precautions, it is very important to fully dissolve the TY1-35 granules in water before adding them to the main treatment bath. This ensures the chemical is evenly distributed and prevents concentrated spots from causing uneven treatment on the fabric.