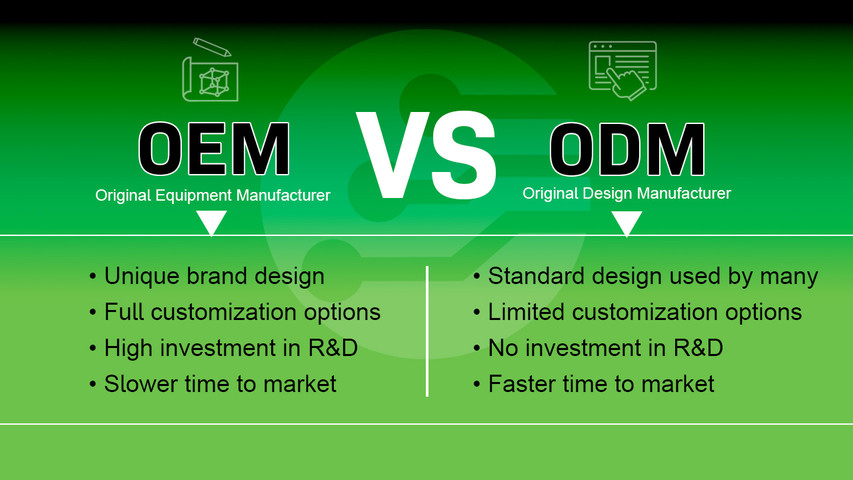

When bringing a new textile chemical product to market, brands and manufacturers face a critical strategic decision: should you develop your own unique formula, or leverage the existing expertise of a manufacturing partner? This decision boils down to a choice between two primary business models: OEM vs ODM textile chemicals. Understanding the difference is key to choosing the right partnership for your business. This clear guide will decode these terms and help you determine which path is best for your brand's growth. For businesses looking for a flexible and experienced partner, exploring our manufacturing services is a great place to start.

What is OEM in the chemical industry? OEM stands for Original Equipment Manufacturer. In this model, you are the "Original Equipment" creator, and the manufacturer acts as your production arm.

The essence of OEM textile chemicals is simple: you provide the complete technical specifications, including the chemical formulation, quality standards, and testing protocols. The chemical manufacturer then uses its facilities and expertise to produce the product exactly as you designed it. You own the product's design and concept.

The biggest advantage of the OEM model is control. You retain 100% ownership of your intellectual property (IP). This is crucial if you have a unique, proprietary formula that gives you a competitive edge. You have full say over every aspect of the product.

The OEM path is ideal for companies with established R&D capabilities. If you have already invested in developing and testing a unique chemical product, partnering with an OEM manufacturer allows you to scale up production without the massive capital investment of building your own factory.

ODM stands for Original Design Manufacturer. This model flips the script: the manufacturer has already done the design and development work.

In an ODM textile chemicals partnership, the manufacturer offers a portfolio of their own pre-developed, market-tested products. You select a product from their catalog, and they produce it for you under your brand name. This is often referred to as private label.

The primary benefit of ODM is speed. Since the product is already developed, you can achieve a much faster time-to-market. You also save significantly on R&D costs and the lengthy process of testing and refinement, as the manufacturer has already done this work.

The ODM model is perfect for brands that want to focus their resources on marketing, sales, and brand building. It allows you to quickly launch a proven product line under your own brand without needing a large in-house technical team.

To help you decide, here's a direct comparison of the two models:

| Feature | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Intellectual Property (IP) | Owned by you (the client) | Owned by the manufacturer |

| R&D Investment | High (done by you) | Low to none (done by manufacturer) |

| Time-to-Market | Slower, requires development first | Faster, uses existing products |

| Product Uniqueness | High, based on your unique formulation | Low, product may be sold to others |

| Control over Product | Full control | Limited to branding and packaging |

The good news is, you don't have to be limited by your choice. A truly capable chemical manufacturer can support you no matter which path you choose. At Taiyang Chemical, we pride ourselves on being a flexible partner for both OEM textile chemicals and ODM textile chemicals.

With our state-of-the-art manufacturing facilities and stringent quality control systems, we are an ideal partner for custom textile chemical production. We have robust protocols in place to protect our clients' intellectual property and can scale production to meet your demands.

We also have a vast portfolio of proven, high-performance textile auxiliaries ready for private label. Our R&D team is constantly innovating, ensuring our ODM clients have access to the latest and most effective chemical technologies on the market.

With over 20+ years of experience, Taiyang Chemical is not just a manufacturer; we are a veteran of the industry. As a leading China textile chemical exporter, we understand the nuances of global markets, quality standards, and supply chain management. This experience is your guarantee of a reliable and successful partnership.

The choice between OEM vs ODM textile chemicals is a strategic one that depends on your resources, goals, and market position. Whether you need a trusted hand to bring your unique vision to life (OEM) or a fast track to market with a proven product (ODM), the key is finding the right manufacturing partner. A flexible, experienced, and trustworthy manufacturer can support your brand's growth at every stage.

Ready to bring your textile chemical product to market? Contact us to discuss your OEM/ODM project and let's build something great together.

What is "private label" and how does it relate to OEM/ODM?

"What is "private label"? *Private label is essentially the outcome of an ODM partnership. It's the process of putting your brand name on a product that was designed and manufactured by another company. It is the fastest way to launch your own product line.

What are the typical minimum order quantities (MOQs) for an OEM project?

MOQs for an OEM textile chemicals project can vary depending on the complexity of the formulation and the raw materials involved. It is generally higher than for an ODM product. It's best to discuss your specific project with the manufacturer to get an accurate quote.

How do you protect my intellectual property (IP) in an OEM partnership?

How do you protect my intellectual property? This is the most critical aspect of an OEM relationship. A reputable manufacturer like Taiyang Chemical will always sign a Non-Disclosure Agreement (NDA) before any technical details are shared. We have strict internal controls to ensure your proprietary *formulation remains confidential.

Can I start with an ODM product and later move to a custom OEM formulation?

Can I start with ODM and move to OEM? Yes, this is an excellent growth strategy. You can start with an ODM product to quickly enter the market and build your brand. As your business grows and you develop more specific needs or *R&D capabilities, you can then work with your manufacturing partner to develop a unique, custom OEM product.