Have you ever wondered what makes your favorite t-shirt so soft, or how your sportswear repels sweat? The answer lies in the unsung heroes of the textile world: auxiliaries. These specialized chemicals are essential for modern fabric production. What are textile auxiliaries, and how do they transform a simple thread into a high-performance fabric? This ultimate guide will walk you through everything you need to know. For a deep dive into our comprehensive solutions, feel free to explore our range of textile chemicals.

You might be asking, what is the difference between a textile auxiliary and a textile chemical? In simple terms, textile auxiliaries are a category of specialized fabric chemicals used during the manufacturing process. They enhance the properties and performance of textiles. They are not the main components like fibers or dyes, but they are crucial support agents.

Think of textile auxiliaries as the "spices" in a recipe. The fiber is the main ingredient, but the spices add color, texture, and special characteristics. These chemicals are vital for achieving specific results in textile finishing and processing. They help make fabrics softer, more durable, or water-repellent. Without them, most modern textiles would not exist as we know them.

It's important to distinguish auxiliaries from other materials. Fibers like cotton and polyester form the basic structure of a fabric. Dyes provide the color. Textile auxiliaries, however, are used to facilitate or improve the dyeing and finishing processes. They ensure that dyes adhere evenly and that the final fabric quality meets high standards. A reliable chemical manufacturer provides a wide range of these essential agents.

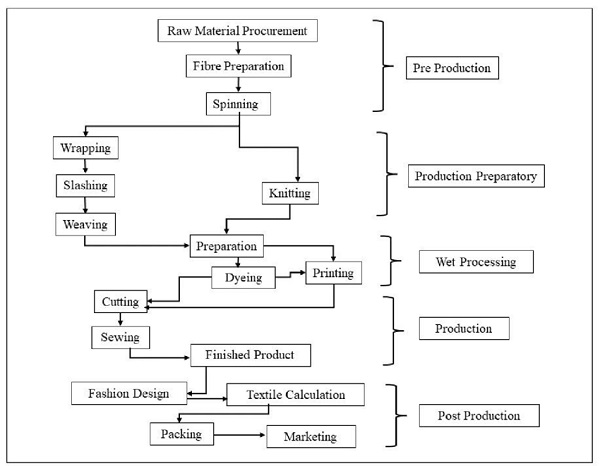

Textile processing chemicals play a vital role at every stage of production. From raw fiber to finished garment, these agents ensure efficiency and quality. Understanding their function in each step is key to appreciating their importance.

Before any color can be applied, the fabric must be perfectly clean. The pretreatment stage removes natural impurities, oils, and sizing agents. Auxiliaries like scouring agents and bleaching stabilizers prepare the fabric for dyeing. This step ensures that the fabric can absorb dye uniformly, creating a flawless final product.

This is where color comes to life. Dyeing auxiliaries are essential for this process. Leveling agents help distribute the dye evenly, preventing blotches and streaks. Fixing agents lock the color into the fibers, ensuring it won't fade after washing. The right choice of auxiliaries here determines the vibrancy and durability of the color.

The final stage, textile finishing, adds value and performance to the fabric. Do you want a fabric to be incredibly soft? You need softeners. Do you need it to be waterproof? You use water-repellent agents. This is where auxiliaries directly impact the consumer's experience. Effective finishing transforms a basic fabric into a premium product.

Why are there so many different types of auxiliaries? The variety of auxiliaries reflects the diverse needs of the textile industry. Each type serves a specific purpose, tailored to different fabrics and desired outcomes. Here are the main categories.

Understanding these categories can help you identify the right solution for your production needs. A knowledgeable textile auxiliaries supplier can guide you through these options.

Selecting the right partner is as important as choosing the right chemical. A reliable supplier offers more than just products; they provide expertise, quality assurance, and a commitment to sustainability. How do I choose the right auxiliary? The answer often lies in your supplier's ability to support you.

The quality of your auxiliaries directly affects your final fabric quality. An inconsistent chemical can ruin an entire batch of fabric, leading to significant financial loss. A trustworthy chemical manufacturer guarantees product consistency, ensuring your production runs smoothly and your products meet specifications every time.

Today's consumers and brands demand eco-friendly products. Working with a supplier that adheres to international standards like OEKO-TEX and ZDHC is essential. It ensures your products are safe and environmentally responsible. This commitment to sustainability is a key factor in modern B2B partnerships.

Challenges in production are inevitable. Having a supplier with strong technical support is invaluable. Whether you're troubleshooting a dyeing issue or developing a new finish, their expertise can save you time and money. Look for a supplier who acts as a partner, not just a vendor. For expert guidance, you can always contact our team of specialists.

Textile auxiliaries are the invisible force that shapes the modern textile industry. From ensuring a flawless pretreatment to creating high-performance finishes, their role is indispensable. Understanding their types and functions allows manufacturers to innovate and create superior products. Choosing a knowledgeable and reliable supplier is the final piece of the puzzle, ensuring quality, consistency, and sustainability. What's the biggest challenge you face with textile auxiliaries in your production? Let us know in the comments below!

1. Are textile auxiliaries safe for skin and the environment? Yes, when sourced from a responsible manufacturer. Reputable suppliers ensure their products comply with strict international standards like OEKO-TEX, which certifies that the final textile product is free from harmful substances. Many modern auxiliaries are designed to be eco-friendly and biodegradable.

2. How do I choose the right auxiliary for a specific fabric like cotton or polyester? The choice depends on the fiber type, the desired effect, and the processing machinery. For example, dyeing auxiliaries for cotton (a natural fiber) are very different from those for polyester (a synthetic fiber). The best approach is to consult with a technical expert. Discover the ideal solutions for your fabric by reaching out to our team.

3. What is the difference between a textile auxiliary and a textile chemical? "Textile chemical" is a broad term that includes all chemicals used in the industry, such as dyes, fibers, and auxiliaries. Textile auxiliaries are a specific sub-category of textile chemicals that assist in the processing stages but are not the primary component of the final fabric.