Ingredients : Blends with decolorizing active products

Appearance : light red liquid

10g/L solution pH : About 5~6

water soluble : Soluble in any concentration

Compatibility : Do not use in the presence of reducing agents, ammonia, chlorine compounds or any acid; avoid mixing with other products

store : When stored under normal storage conditions at 5-30°C and in sealed original packaging, it is stable for 6 months

TY4-18 PP Substitute is a ready-to-use product designed for the partial decolorization of denim garments, a process commonly known as "spraying a monkey" or creating "nimbus" effects. It delivers excellent results on all types of denim fabrics, including those with stretch yarn, indigo, or vulcanized dyes.

Patent qualification

Factory

Shipping

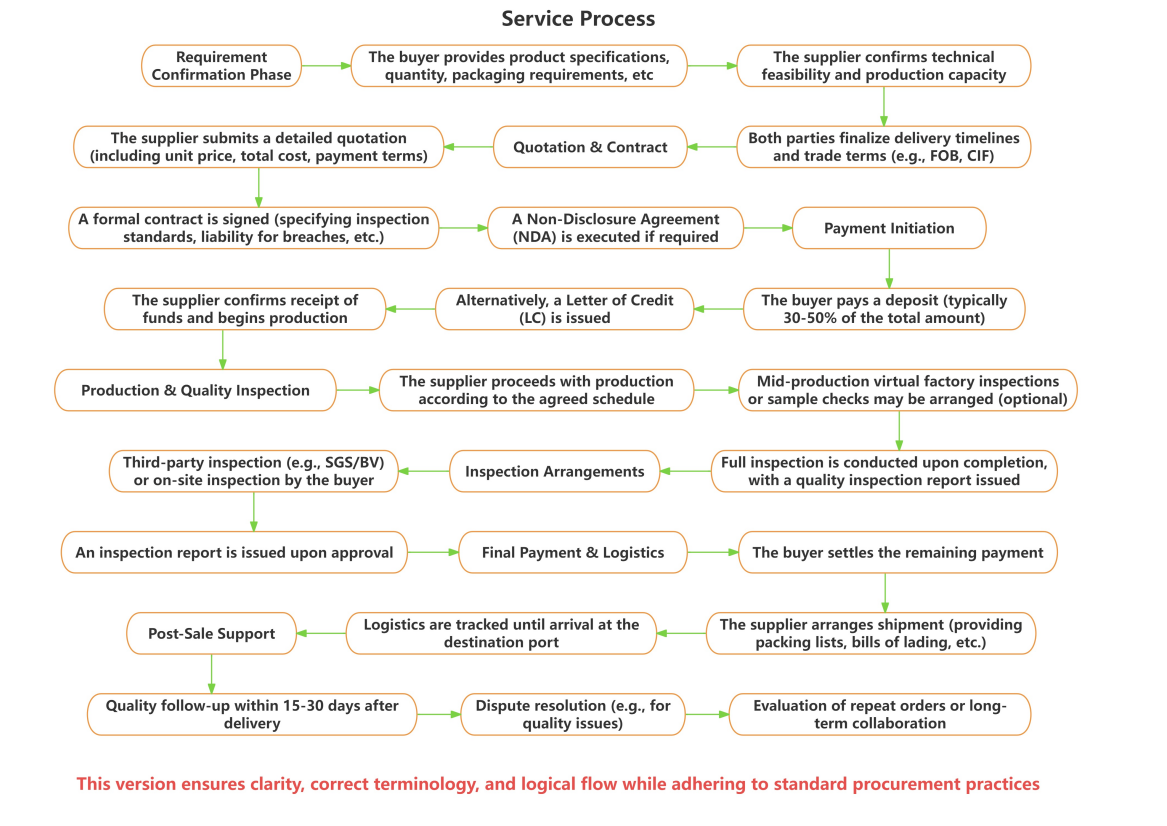

Service process