Product Attributes

Main Components : Compound of surfactants and various silicones

Appearance : Off-white to light yellow paste

Ionicity : Weak cationic

pH Value : 5.0–7.0 (1% aqueous solution)

Product introduction

TY3-23B is a high-performance low-yellowing soft paste, formulated as a compound of surfactants and various silicones. It is suitable for finishing all kinds of knitted and woven fabrics, providing a comprehensive hand feel that is simultaneously soft, smooth, delicate, and resilient.

This product is widely used in the soft finishing of natural fibers such as cotton and linen, as well as various blended fibers. Due to its exceptional process stability, it is especially suitable for the demanding environment of dyeing plants.

Key Characteristics & Performance Advantages

Versatile Application & Superior Hand Feel:

Widely applicable to cotton, linen, synthetic fibers, and their blends.

It imparts an outstanding resilience, a delicate touch, and a soft-smooth hand feel to treated fabrics.

Excellent Process Stability:

The formula shows excellent resistance to salt, alkali, and high shear forces.

This high stability makes it especially suitable for use as an in-bath softener in dyeing plants, where it performs reliably in complex chemical environments.

Very Low Yellowing:

It exhibits very low yellowing, making it suitable for a wide range of medium and light-colored fabrics.

It has minimal impact on the original fabric shade, preserving color integrity.

Easy to Rework:

In the rare case of an issue, the finish can be easily repaired with simple treatment, with no color spots after repair.

Recommended Application Methods

It is recommended to dilute the paste at a ratio of 1:5 to 1:10 before use.

Dilution Method (Example for 1:10)

To prepare one ton of 10% solution, a step-wise dilution process is recommended to ensure a uniform mixture. Please refer to the detailed technical data sheet or contact our support team for the precise procedure.

Padding Method

Dosage: 20–50 g/L (of diluted solution)

Temperature: Room Temperature

Process: One dip one nip, or two dips two nips

Exhaust Method (In-Bath)

Dosage: 1–5% (o.w.f) (of diluted solution)

Temperature: 30–40°C

Liquor Ratio: 1:10–15

Time: 5–30 min

Application Range

TY3-23B is widely used in various knitted and woven dyeing plants. It is suitable for the hand-feel finishing of:

Cotton

Linen

Synthetic fibers and their blended fabrics

Storage and Packaging

Storage: When stored at room temperature in the original packaging and placed in a clean, covered, and suitable container, this product poses no handling or storage difficulties.

Packaging: Available in 50 KG and 125 KG plastic drums.

Shelf Life: 6 months.

Illustrate (Technical Note)

The technical advice provided herein is for reference only, based on controlled laboratory or pilot-scale experiments. The buyer must confirm through testing whether the product is suitable for their process and desired outcome under expected usage conditions. Our company only guarantees that the product meets specifications. The user's sole compensation and our sole liability are limited to product replacement.

About us

Patent qualification

Factory

Shipping

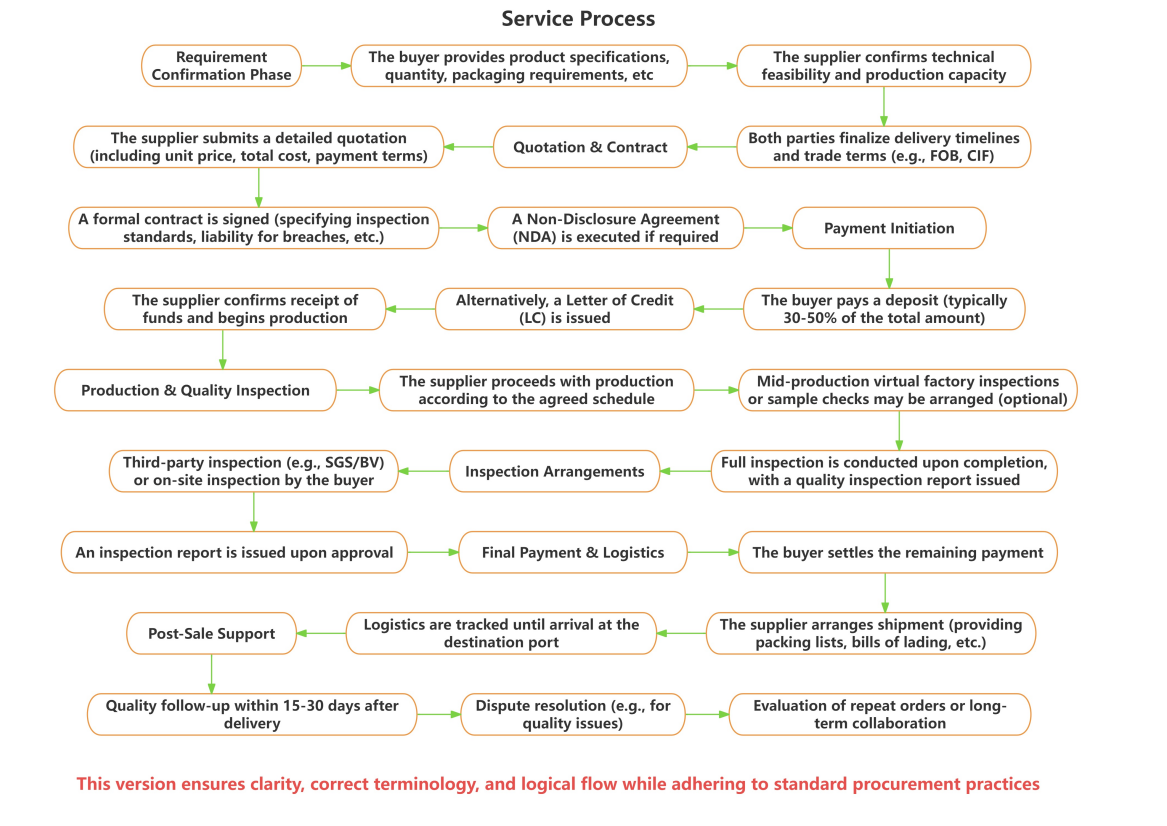

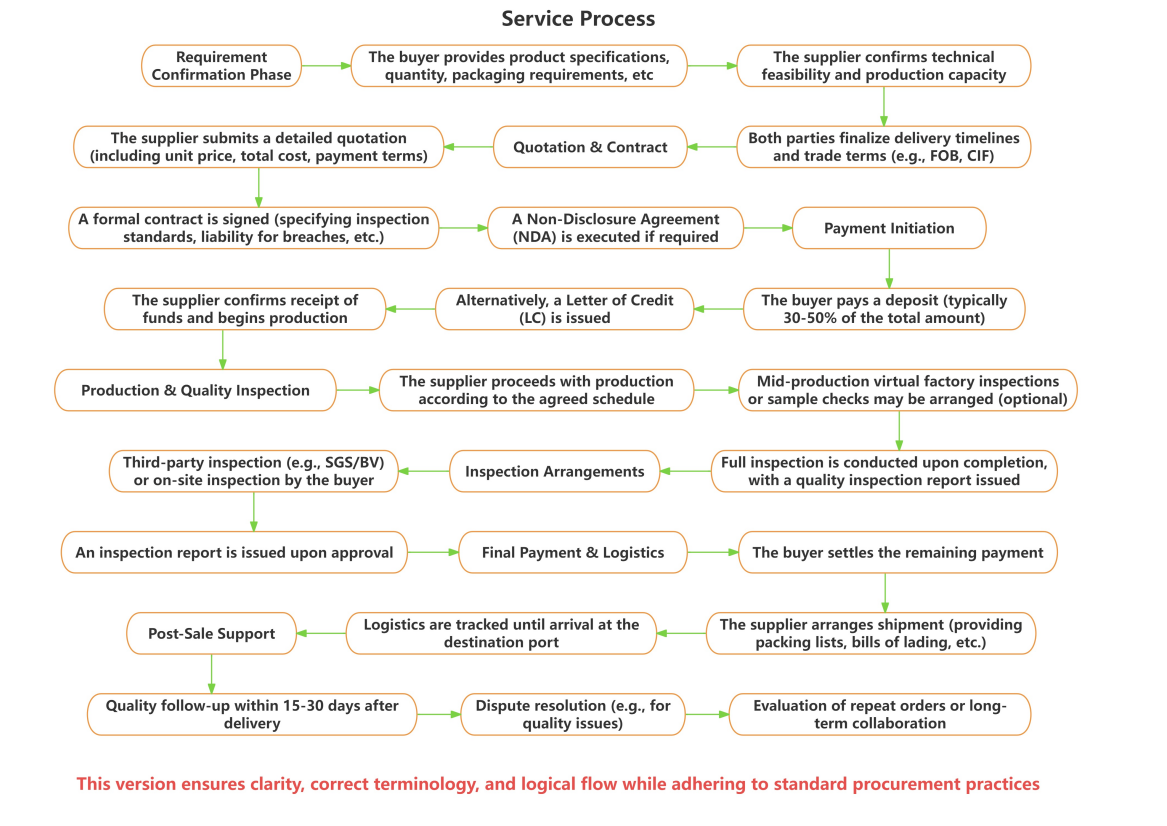

Service process