Main Ingredients : Compound of magnesium salt and surfactants

Appearance : Light-colored to light yellow transparent liquid

Ionicity : Anionic/Nonionic

pH Value : 4.0–6.0

Stability : Alkali-resistant, electrolyte-resistant

TY1-32 is a high-performance oxygen bleaching stabilizer used during the fabric bleaching process. Its primary function is to stabilize hydrogen peroxide (H₂O₂), controlling its decomposition rate to prevent fabric damage such as pinholes and strength loss. It provides a crucial protective effect, ensuring a safe and effective bleaching outcome.

Patent qualification

Factory

Shipping

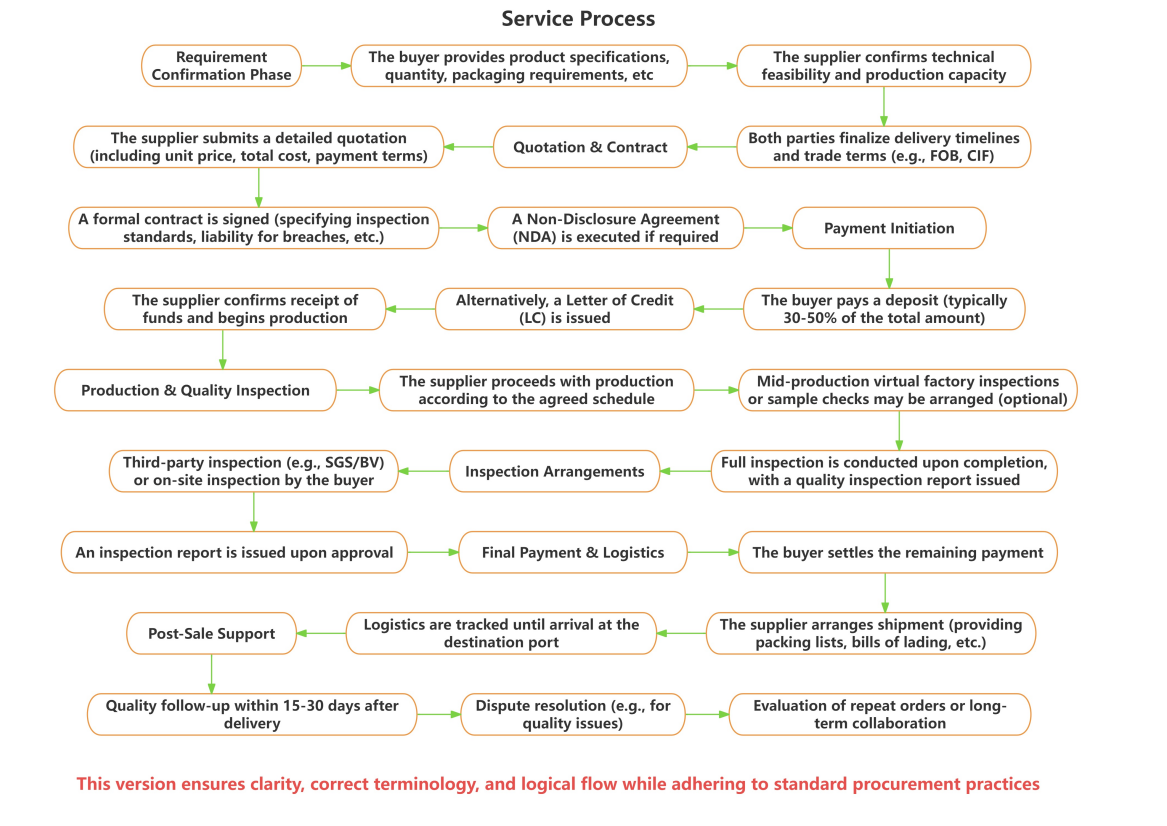

Service process