Product Attributes

Appearance : Light yellow viscous liquid

Lonicity : Cationic / Nonionic

PH Value : 5.0 ± 1.0 (1% aqueous solution)

Product introduction

TY-8807A2 is a special cationic modifier, formulated as a high-performance cationic polymer. When it reacts with cellulosic fibers like cotton, it transforms the fibers' surface charge to cationic. This modification significantly improves the dye uptake of anionic dyes, such as reactive and direct dyes.

It is primarily used as a dyeing intensifier and fixing agent for cotton fabrics, and is also highly effective for improving the leveling of R/C (rayon/cotton) fabrics. Furthermore, it is a key auxiliary for garment pigment dyeing and pigment overdyeing in denim processing.

Key Features & Performance Advantages

High Dye Uptake: The primary benefit is a high dye uptake rate, leading to deeper shades with less dye consumption. It's an easy-to-use solution for intensifying colors.

Improves Levelness: It significantly improves uneven dyeing issues, particularly in difficult-to-dye R/C fabrics, resulting in a more uniform and consistent color.

Enhances Pigment Performance: In pigment dyeing applications, it enhances pigment uptake and improves the final soaping fastness, leading to a more durable and wash-resistant finish.

Eco-Friendly Formula: This product is free from free formaldehyde and is an environmentally friendly choice for modern textile pretreatment.

Recommended Application Process

The following process for R/C knit fabric dyeing is provided as an example. The pretreatment step is also applicable for deepening the color of cotton with anionic dyes.

Process Flow: Pretreatment → Rinsing → Dyeing → Post-treatment → Drying

1. Pretreatment (Modification)

Modifier Dosage: 3–5% (o.w.f) - (Add 3–5 KG of product per 100 KG of fabric)

Temperature & Time: 40–60°C for 20–40 minutes

2. Rinsing

Method: Cold water treatment. Adequate rinsing is crucial to prevent dyeing defects. Rinsing twice is recommended.

3. Dyeing

Note: This auxiliary is not suitable for use in pre-alkaline dyeing processes. For the most even dyeing results, a stepwise addition of salt and alkali is recommended.

4. Post-treatment

Method: Follow the same procedure as your conventional dyeing process.

Scope of Application

TY-8807A2 is mainly used for:

Fabric modification before pigment dyeing of cotton fabrics.

Modification in reactive dyeing to improve dye uptake and levelness.

Leveling dyeing of R/C fabrics.

Pigment overdyeing in denim processing.

Storage and Packaging

Storage: Store at room temperature in the original, sealed packaging. Kept in a clean, covered, and suitable container, this product presents no handling or storage difficulties.

Packaging: Available in 50 KG and 125 KG plastic drums.

Shelf Life: 6 months.

Illustrate (Technical Note)

The technical advice provided herein is for reference only, based on controlled lab or pilot tests. It is the buyer’s responsibility to conduct their own experiments under expected usage conditions to verify whether the product is suitable for their specific process and intended use. Our company guarantees only that the product meets the specified standards. The user's sole remedy and the company's only obligation are limited to product replacement.

About us

Patent qualification

Factory

Shipping

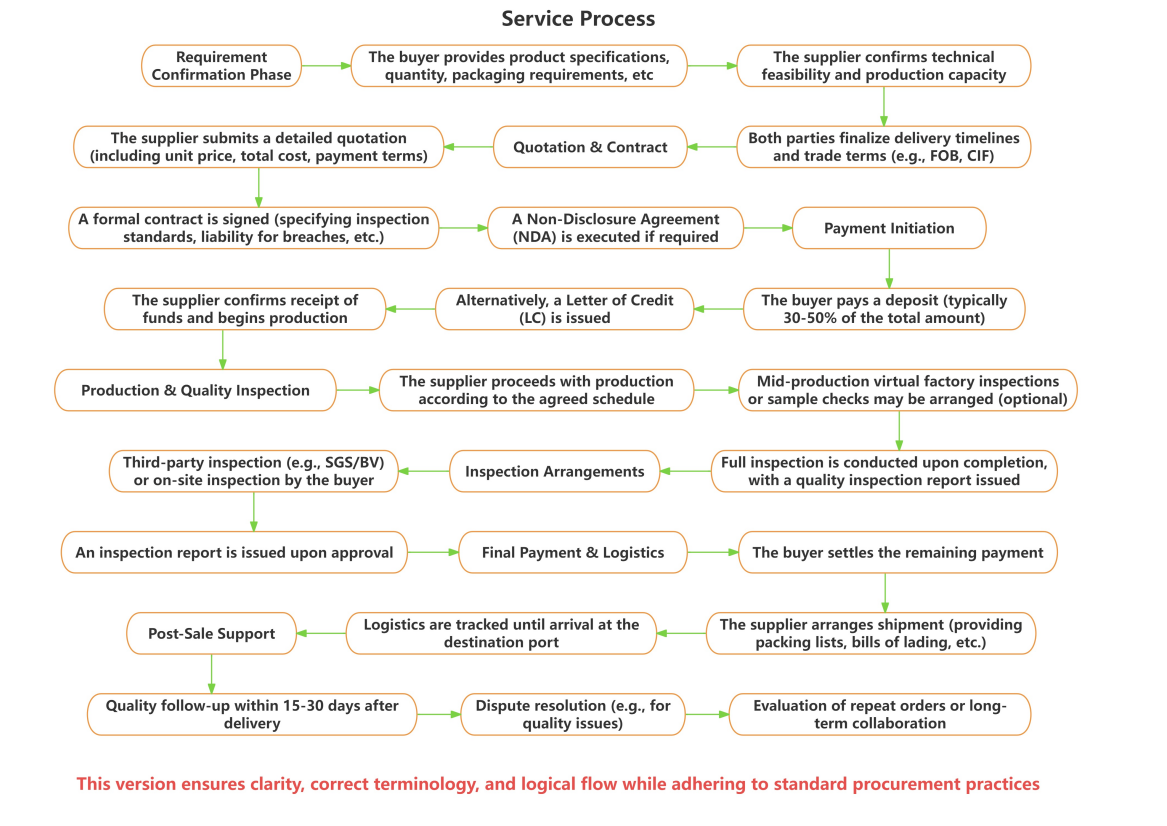

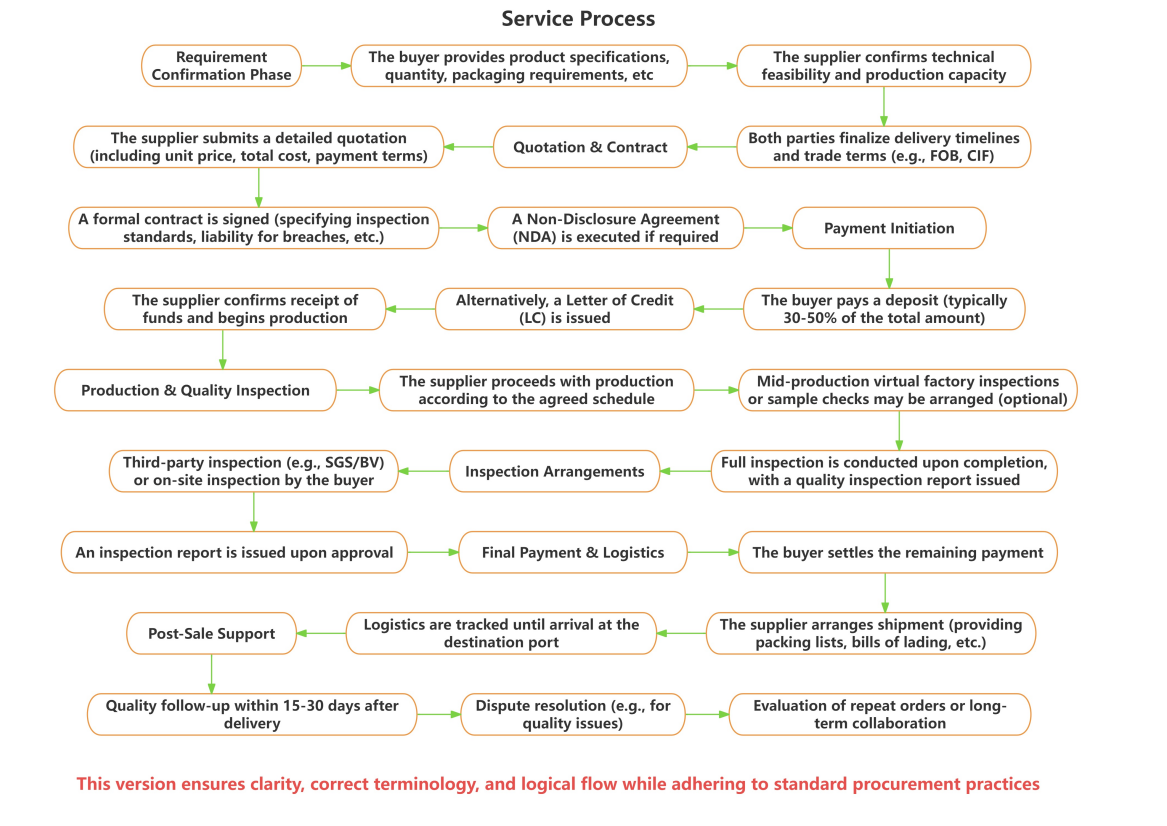

Service process