In the world of textile finishing, achieving the perfect soft hand feel is the ultimate goal. The choice of fabric softener is one of the most critical decisions a manufacturer makes, directly impacting the final product's quality, durability, and consumer appeal. The two dominant players in this field are traditional fatty acid-based softeners and modern silicone oils. Which fabric softener should you use? This head-to-head comparison will break down the silicone oil vs fatty acid softener debate, helping you make the best choice for your fabrics. For those seeking advanced solutions, you can explore our high-performance silicone oil range.

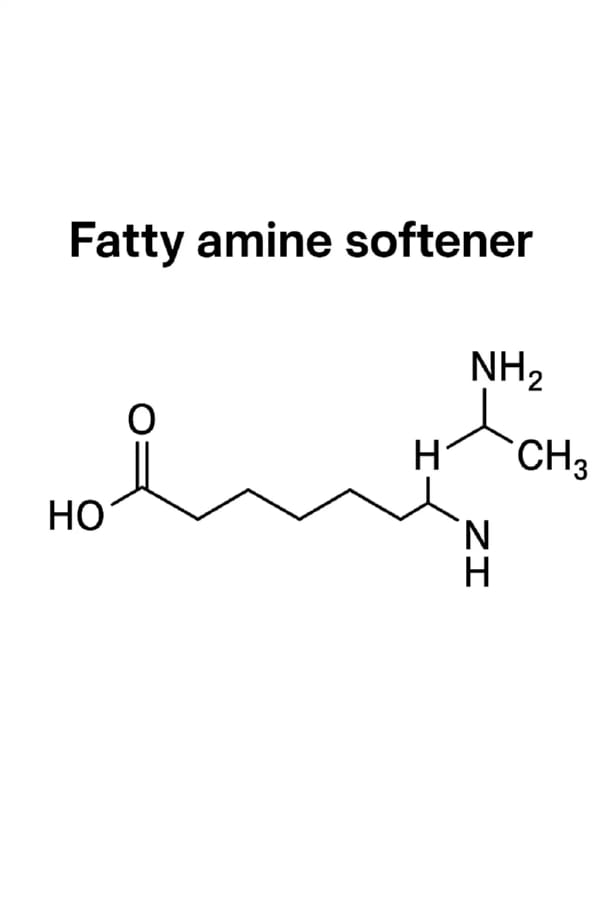

Fatty acid-based softeners are the traditional workhorses of the textile industry. They are typically derived from natural fats and oils, such as tallow or vegetable sources.

The chemical composition of these softeners consists of long hydrocarbon chains. When applied to fabric, these molecules align on the fiber surface, creating a waxy, lubricating layer. This layer reduces friction between the fibers, which the user perceives as softness. Their action is primarily physical and surface-level.

The primary advantage of fatty acid softeners is their cost-effectiveness. They are generally less expensive to produce, making them a popular choice for large-scale, budget-conscious production. Additionally, many are derived from natural sources, giving them good biodegradability, which is a plus for certain environmental profiles.

However, these softeners have significant limitations. They are prone to oxidation, which can lead to yellowing, especially on white or light-colored fabrics when exposed to heat. Their wash durability is often poor, meaning the softening effect diminishes after just a few laundry cycles. Some formulations can also leave a slightly greasy or waxy residue, affecting the fabric's natural texture.

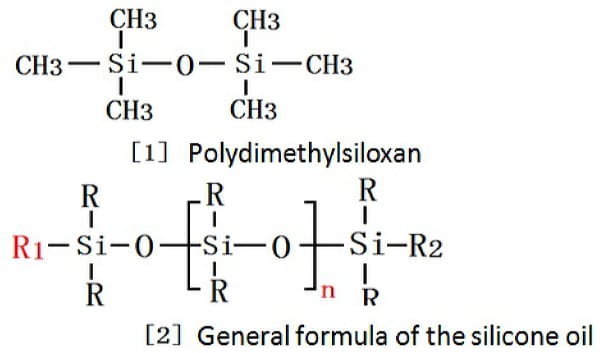

Silicone oil for textiles represents a significant technological advancement in fabric finishing. These synthetic polymers, based on a polysiloxane structure, offer a level of performance that traditional softeners often cannot match.

The science of silicone lies in its flexible molecular backbone of silicon and oxygen atoms. This structure allows silicone oil to spread into a very thin, durable, and elastic film over the fibers. This film provides exceptional lubrication with minimal substance, resulting in a superior soft hand feel that is often described as silky and smooth.

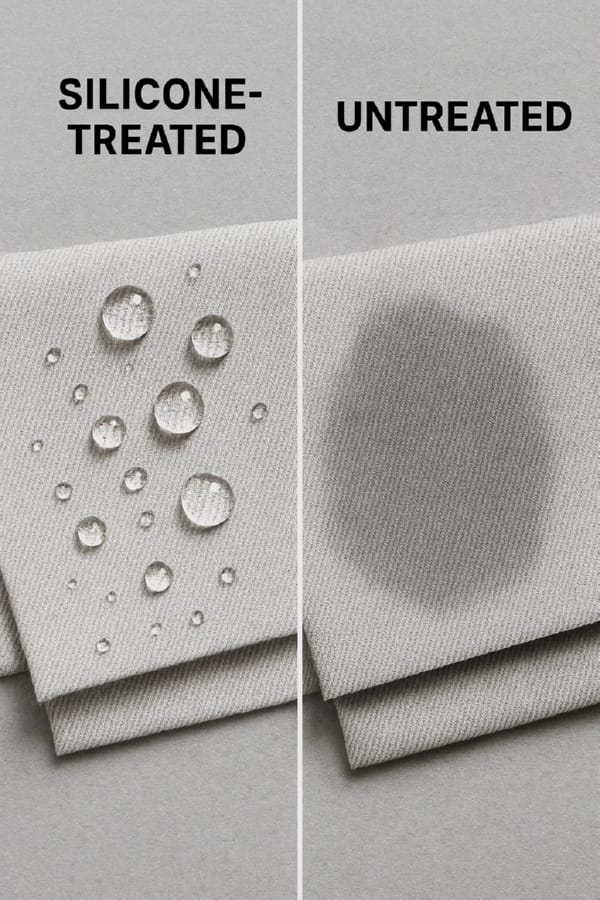

The superior performance of silicone oil is its main selling point. It imparts a deep, inner softness rather than just a surface slickness. Fabrics treated with silicone oil exhibit excellent smoothness, drape, and resilience, meaning they resist wrinkling and recover their shape more easily. This is crucial for premium garments and high-performance textiles.

Modern silicone oils are engineered for advanced benefits. Formulations like our TY-8809A2 offer excellent low yellowing properties, making them ideal for whites and pastels. Their chemical bond to the fibers ensures high wash durability. Furthermore, specialized silicone oils can be designed to maintain or even enhance hydrophilicity (water absorbency), a critical feature for products like towels and sportswear that fatty acid softeners often impair.

To make the choice clearer, here is a direct comparison across key metrics:

| Feature | Fatty Acid Softener | Silicone Oil Softener |

|---|---|---|

| Hand Feel | Waxy, surface softness | Silky, smooth, deep softness, excellent resilience |

| Durability | Low wash durability | High wash durability, long-lasting effect |

| Yellowing | Prone to yellowing | Excellent low yellowing properties |

| Fabric Impact | Can feel greasy, reduces absorbency | Non-greasy, can be hydrophilic |

| Cost | Lower initial cost | Higher initial cost, better long-term value |

| Versatility | Limited applications | Highly versatile for denim, synthetics, blends |

The decision ultimately depends on your product's quality standards, performance requirements, and budget.

Fatty acid softeners are a viable option for basic, cost-sensitive items where a simple softening effect is sufficient and long-term durability is not a primary concern. They are often used for disposable textiles or in markets with extreme price pressure.

For any product where hand feel is a key selling point, silicone oil is the superior choice. This includes premium garments, denim (where it enhances softness without a greasy feel), home textiles like bed linens and towels, and any fabric requiring high wash durability and resilience.

It's not always an "either/or" situation. In some applications, blended formulations that combine the cost-effectiveness of fatty acids with the performance of silicones can offer a balanced solution. A skilled silicone oil wholesale supplier can provide such customized products. To learn more about custom solutions, feel free to contact our technical team.

While both softeners have their place, the silicone oil vs fatty acid softener comparison clearly shows that for quality, performance, and versatility, silicone oil is the modern standard. By investing in advanced softening technology, you elevate your fabric's value and exceed consumer expectations. The superior soft hand feel, durability, and resistance to yellowing make it the smart choice for manufacturers aiming for the top tier of the market.

Ready to experience the superior feel of silicone oil? Contact Taiyang Chemical, a leading silicone oil wholesale supplier, for samples and technical data.

1. Is silicone oil more expensive than fatty acid softeners? Initially, the per-kilogram cost of silicone oil is higher. However, it is often used at a lower dosage and provides a much more durable effect, which means better long-term value and fewer consumer complaints. The enhanced quality can also justify a higher price for the final garment.

2. Can silicone oil be used on all types of fabrics? Yes, silicone oils are incredibly versatile and can be formulated for virtually all fiber types, including cotton, polyester, nylon, wool, and their blends. Different silicone chemistries (e.g., amino, hydrophilic) are used to achieve specific effects on different substrates.

3. What does "low yellowing" actually mean for a softener? Low yellowing means the softener will not cause a noticeable yellowish tint on white or light-colored fabrics, even when exposed to high temperatures during drying or long-term storage. This is a critical quality parameter for maintaining the original shade of the fabric.

4. How do I find a reliable silicone oil manufacturer? Look for a silicone oil manufacturer with a strong R&D department, a wide range of products, and excellent technical support. A reliable supplier, like Taiyang Chemical, will provide consistent quality, compliance with standards like OEKO-TEX, and the expertise to help you choose the perfect formulation for your needs.