The thermosol dyeing process is a cornerstone of high-efficiency polyester dyeing, prized for its speed and continuous operation. However, this method faces a persistent technical challenge: dye migration. This phenomenon can lead to costly color defects, ruining entire batches of fabric. This guide provides an expert look at dye migration control, explaining the causes and introducing effective solutions. For manufacturers seeking flawless color consistency, understanding these principles is key. Explore our advanced dyeing auxiliaries to perfect your process.

What is dye migration? In the context of thermosol dyeing, it is the movement of disperse dye particles along with water as the fabric dries. This movement occurs between the padding stage and the final heat-setting (thermofixation) stage. Because the drying is rarely perfectly uniform, this leads to an uneven distribution of dye across the fabric.

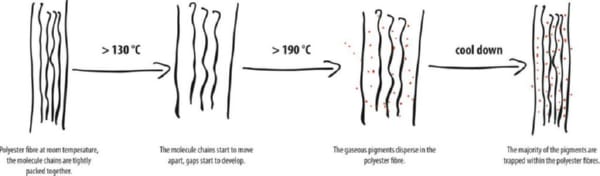

When padded fabric enters the drying chamber, water evaporates from the hotter or more exposed areas first. Capillary action then draws more water—and the dye particles suspended in it—from wetter areas to these drier zones. This results in a higher concentration of dye in certain parts of the fabric, causing uneven color.

Uncontrolled dye migration is a primary source of quality issues in continuous dyeing. The most common color defects include:

To solve this problem, the industry uses a specific category of pad dyeing auxiliaries known as anti-migration agents or, more commonly, anti-slip agents. How do anti-migration agents work? Their effectiveness comes from a two-pronged approach to control the dye within the wet fabric.

The primary function of an anti-slip agent is to slightly increase the viscosity of the pad liquor (the dyeing solution). This makes the water less mobile within the fabric's capillary structure. By slowing down the movement of water towards the drying zones, it significantly reduces the migration of the dye particles along with it.

Some advanced anti-migration agents also help promote a weak, temporary adhesion between the dye particles and the fiber surface immediately after padding. This "tacks" the dye in place, further preventing it from moving during the critical drying phase, ensuring better leveling.

At Taiyang Chemical, we offer TY2-52 Anti-Slip Agent, a practical and highly effective tool for dye migration control in your polyester dyeing line. This product is engineered to provide maximum control with minimal impact on your final product.

The key benefit of TY2-52 is its powerful ability to inhibit dye migration, which directly translates to improved color uniformity and better leveling. By using this agent, manufacturers can drastically reduce instances of shading and streaks, leading to a higher first-pass quality rate and less waste.

TY2-52 is a viscous liquid that is easily soluble in water. For most pad dyeing applications, we recommend a dosage of 10–30 g/L in the dyeing bath. It is added along with the other dyeing auxiliaries to create a stable and effective pad liquor.

A critical advantage of TY2-52 is that it is non-sticky. This prevents buildup on guide rollers and equipment, ensuring a smooth and uninterrupted production run. Furthermore, it is hand-feel neutral, meaning it does not leave any harsh or stiff residue on the final fabric, preserving the desired texture. For those needing specific solutions, our custom textile chemical production can help.

Using an anti-slip agent is most effective when combined with optimized process controls. The chemical and the machinery should work in harmony.

Ensure your pad pressure is even across the fabric width to guarantee uniform pickup. In the dryer, aim for the most uniform temperature and airflow possible. Even drying is the best partner to an effective anti-migration agent.

TY2-52 is designed for high compatibility with other common dyeing auxiliaries used in polyester dyeing, such as dispersing agents and pH buffers. Always ensure all components are fully dissolved and mixed before starting the padding process to create a stable dyeing system.

Dye migration control is fundamental to achieving high-quality results in continuous thermosol dyeing. While process control is important, the use of a specialized, high-performance anti-slip agent like TY2-52 is the most reliable way to prevent costly color defects. By investing in the right pad dyeing auxiliaries, you can ensure perfect color uniformity, reduce waste, and enhance your reputation for quality.

Eliminate costly color defects from your production line. Discover more about TY2-52 Anti-Slip Agent and get a technical consultation for your thermosol dyeing process.

1. What is the difference between an anti-migration agent and a leveling agent? While both aim for uniform color, they work differently. An anti-slip agent (anti-migration agent) physically prevents dye from moving during drying. A leveling agent works during the dye fixation stage, helping dye molecules distribute evenly by controlling their absorption rate onto the fiber. They are often used together.

2. Can I use a simple thickener instead of a specialized anti-migration agent? While a simple thickener can increase viscosity, it is not recommended. Specialized anti-migration agents like TY2-52 are formulated to be non-sticky and not interfere with the final hand feel or dye yield. Simple thickeners can cause roller buildup and leave the fabric feeling harsh.

3. Does TY2-52 Anti-Slip Agent work for pigment pad dyeing as well? Yes. According to our product data, TY2-52 is also highly effective in preventing migration during pigment pad dyeing processes, making it a versatile tool for any continuous coloring line.

4. How does uneven drying affect dye migration? Uneven drying is the primary driver of dye migration. The faster-drying areas act like a wick, pulling dye-laden water from slower-drying areas. The more uneven the drying, the more severe the migration and the resulting color defects will be. That's why pairing an anti-migration agent with optimized drying conditions is the best strategy. To discuss your specific process, feel free to contact our experts.