In a busy dye house, there's no sight more dreaded than opening a machine to find a full batch of fabric with dyeing defects. Whether it's uneven dyeing, color spots, or batch-to-batch inconsistencies, these issues can halt production and lead to massive financial losses. Traditionally, the only option was a harsh cycle of stripping and re-dyeing. But what if there was a smarter way? This guide explores modern color correction for dyed fabrics, focusing on the power of high temperature repair agents to salvage your production. For those facing these challenges, it's time to discover a more efficient solution from a leading high temperature repair agent factory.

Polyester dyeing is a precise science, and even minor deviations can result in significant quality problems. Understanding these defects is the first step to appreciating the need for an advanced repair solution.

This is the most frequent issue. It can manifest as dark color spots, light patches, or gradual shading from one side of the fabric to the other. These issues make the fabric unsellable and are a clear sign that the dye has not been distributed uniformly.

Maintaining perfect color consistency across multiple batches is a major challenge. Even slight variations in process parameters can lead to noticeable color differences, disrupting the supply chain for garment manufacturers.

The conventional fix for these problems is chemical stripping followed by a complete re-dyeing cycle. This process is not only expensive in terms of chemicals, water, and energy, but it's also time-consuming and can cause significant fiber protection issues, potentially weakening and damaging the fabric permanently.

How do high temperature repair agents work? Unlike stripping agents that chemically remove color, repair agents utilize the principle of dye migration to fix the problem intelligently. They are a cornerstone of modern color correction for dyed fabrics.

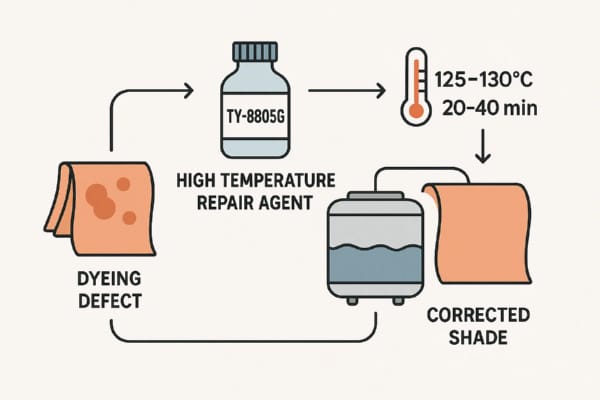

A high temperature repair agent is a specialized chemical that, under the high temperature (typically 125-130°C) and pressure of a polyester dyeing machine, encourages disperse dye molecules to detach from the fiber. It then helps them move through the dyebath from areas of high concentration to areas of low concentration, effectively leveling out the color.

The most significant advantage of this method is that it achieves leveling without substantially changing the overall color shade or depth. It redistributes the existing dye rather than removing it. This means you can fix uneven dyeing issues while preserving the original target color, a feat impossible with traditional stripping.

To empower dye houses with this advanced capability, Taiyang Chemical has developed TY-8805G High Temperature Repair Agent. This product is the ultimate tool for salvaging batches and turning potential losses into profitable products.

TY-8805G is formulated with powerful surfactants that provide exceptional dye migration ability. Its excellent dispersibility ensures that the mobilized dye particles are kept stable in the bath, preventing them from re-agglomerating and causing new spots.

This product is incredibly versatile. Its primary use is for color repair of dyeing defects. However, it can also be used in lower concentrations as a high-performance leveling agent in initial dyeing. Furthermore, in combination with reducing agents, it can act as a booster for stripping processes, making them faster and more effective.

For color repair, a typical dosage is 0.5-1.5 g/L. The process is run at 125-130°C for 20-40 minutes. These conditions are standard for polyester dyeing, making it easy to integrate into your existing workflow without special equipment. You can always request our technical data sheet for precise parameters.

Making the switch to a modern repair agent is a strategic business decision with clear benefits.

| Feature | Traditional Stripping & Re-Dyeing | High Temperature Repair Agent |

|---|---|---|

| Time & Cost | Very high; two full process cycles | Low; a single, short repair cycle |

| Fiber Protection | High risk of fiber damage and strength loss | Minimal impact on fabric integrity |

| Control | Low; final color is unpredictable | High; preserves original shade |

| Overall Value | Last resort, high risk | First-line solution, high time and cost savings |

Dyeing defects in polyester dyeing no longer have to mean a complete loss. With a modern high temperature repair agent like TY-8805G, you can turn a problematic batch into a first-quality product. This approach to color correction for dyed fabrics saves time, money, and resources while ensuring superior fiber protection. It's a smarter, more sustainable way to manage quality control in the dye house.

Don't let dyeing defects drain your profits. Contact a leading High Temperature Repair Agent factory to learn how TY-8805G can salvage your production.

1. Will using a repair agent like TY-8805G cause my fabric to lose its color depth? No, this is one of its main advantages. When used for color repair, TY-8805G primarily redistributes the dye to correct unevenness. It does not chemically strip the color, so the impact on the overall color depth and shade is minimal, preserving your original target.

2. What is the difference between a high temperature repair agent and a high temperature leveling agent? While their functions overlap, a high temperature repair agent is specifically formulated with a stronger migration-promoting ability to correct existing, significant dyeing defects. A leveling agent is typically used during the initial dyeing cycle to prevent those defects from forming in the first place. TY-8805G is powerful enough for repair but can also be used as a high-performance leveling agent.

3. Can TY-8805G be used for fibers other than polyester? TY-8805G is specifically designed for disperse dyes on polyester and its blends under high-temperature conditions. It is not recommended for other fiber types like cotton or nylon, which require different dyeing systems and chemistries.

4. How do I perform a lab trial to test the effectiveness of this repair agent? We highly recommend lab trials. Take a sample of your fabric with the uneven dyeing defect and treat it in a lab dyeing machine using the recommended dosage and process conditions. Compare the treated sample with the original to evaluate the leveling effect. To get started, contact us to request a sample of TY-8805G.